In many warehouses and distribution centers, a loading dock is the center of a lot of activity. For most companies, the dock is where supplies come in and where products go out. As one of the key “organs” of your company’s “body”, loading docks give shipping trucks and personnel easy access to storage areas and make delivering items – or loading them up for delivery elsewhere – a snap. However, when considering all the different environments in a facility, a loading dock just might be an area filled with hazards.

The United States Occupational Safety and Health Administration has standards for loading docks just like everything else, and most of their regulations have to do with running forklifts on the docks. Requirements for forklift operator training and standards for “walking and working surfaces” (in other words, preventing slipping and falling) are just one part of OSHA’s printed regulations. Serious injuries can occur on loading docks due to forklift-human collision, slipping, unsecured or improperly secured pallet loads, improperly used tools, trash or unnecessary items on the ground, chemical spills, or lifting too much weight.

Making your docks safe for everyone – your employees and outside delivery personnel alike – should be a top priority for anyone in the warehousing and distributing fields. It can be challenging to make safety a priority and to maintain it as the months and years go by.

Here are a few tips to get started on loading dock safety:

Make sure your personnel receive dock safety training. Just as importantly, make sure all safety rules get enforced! That can be a crucial point if overlooked, because all the rules and training in the world won’t matter if there isn’t any enforcement.

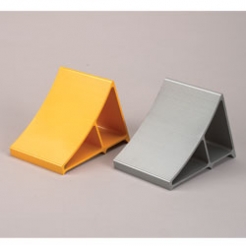

Ensure that vehicles use wheel chocks. These are sturdy wedges that you put behind a vehicle’s wheels, preventing accidental movement, such as trailer creep. The bottom of some chocks are rubber-coated to enhance gripping. Chocks must always be used in addition to – not in place of – setting the brakes!

Powered truck operators must be trained to yield the right of way to pedestrians at all times. This is proven to significantly cut down or eliminate minor and major injuries as a result of lift truck-human collisions. Other safety considerations for people moving around the facility may include using yellow paint or floor striping tape to identify walkways, doorways, parking areas, and overhead hazards. You can also place pads or guards around sharp corners or other objects to prevent injuries caused by “walking into” or “bumping” something sharp.

Today we’ve reviewed a handful of safety-related ideas for improving your warehouse or distribution center’s loading docks. In the future, we’ll go over even more safety tips!