Forklifts are an essential piece of equipment for practically every warehouse, manufacturing facility and other businesses today. These durable, hard-working vehicles provide one of the fastest, most efficient and cost-effective ways to keep business running productively and profitably.

Forklifts are an essential piece of equipment for practically every warehouse, manufacturing facility and other businesses today. These durable, hard-working vehicles provide one of the fastest, most efficient and cost-effective ways to keep business running productively and profitably.

Yet forklifts are also enormously powerful and extremely heavy. When they aren’t used properly and with the utmost safety measures, they can potentially result in lost product, property damage, injuries to workers or pedestrians, and even death.

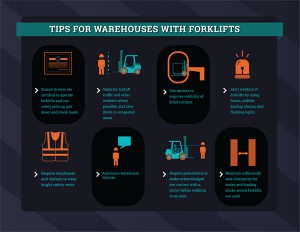

In honor of the first-ever National Forklift Day, which is being held on June 10, we are going to review the eight most important forklift safety rules that should be followed whenever one of these helpful yet potentially dangerous vehicles are being used:

1. Ensure Operators are Qualified

Federal law requires that anybody operating a forklift or other heavy machinery be thoroughly trained and certified on its safe operation. While the federal agency enforcing that law — the US Occupational Safety and Health Administration — doesn’t usually conduct spot inspections, it’s a safe bet that if there is a serious forklift accident at your facility, inspectors will show up demanding to see your training and certification documentation. If you can’t provide it, you could be in serious trouble.

2. Whenever Possible, Separate Vehicle from People

Clear paths should be provided wherever forklifts are being used. These vehicles can weight several tons — even without their payloads. And operators often have restricted view and aren’t always aware when other people are around. That’s why it’s always a good idea to keep forklifts away from other workers, and vice versa, whenever possible.

3. Mirrors Help Increase Visibility Around Corners

When drivers are approaching blind corners, they can’t see what’s coming. You can decrease your chances of a collision or other accident by installing affordable, safety-promoting mirrors high up at the facility’s busiest intersections.

4. Make Sure Workers Know When Forklifts Are Around

Workers are often caught up in their own little world, especially today when so many people are staring at their mobile devices rather than where they are going. Make sure forklift operators are constantly using their horns, audible backup alarms, flashing lights and other alerts to make workers aware when forklifts are in the area.

5. Bright Safety Vests Save Lives

Require anybody working with or near forklifts to wear florescent colored safety vests so operators and pedestrians can always see each other.

6. Announce All Visitors to the Facility

It’s always a good idea to let workers know when somebody new is in the facility so they can take extra precautions. Visitors may not be familiar with your safety protocols, so it’s up to your employees to help keep them safe.

7. Promote Eye-to-Eye Contact

The easiest way to be sure pedestrians an forklift operators to see each other is to require them to make eye-to-eye contact when both are an area where the vehicles are being used.

8. Give Forklifts Enough Room to Operate Safely

Forklifts are heavy-duty vehicle that can’t stop or turn on a dime. They require a lot of room to maneuver, especially when they are hauling a heavy payload. Make sure you provide safe clearances in aisles and on loading docks so that you can facilitate the safe and efficient operation of these vehicles.